Mechanical and Materials Engineering

Scott Schrage, April 28, 2023

Team IDs emergence of surprising layers in nanomaterial

FINDINGS COULD GUIDE TECH INTEGRATION OF FLEXIBLE, LOW-COST POLYMER

By melting a polymer and watching it cool through the lenses of light and X-rays, University of Nebraska–Lincoln engineers have discovered hidden depths in a material hundreds of times thinner than a human hair.

Those depths — specifically, an ultra-thin crust and the mantle beneath it — can solidify and crystallize in different ways, the team found. The differences are more than superficial: They can alter the transport of electric charges and other technologically relevant properties of the polymer, which is known as P3HT and features a lightweight flexibility that appeals to designers of next-gen electronics.

Lucía Fernández-Ballester and her colleagues hope that observing and reporting the never-before-seen intricacies of P3HT’s crystallization will ultimately help engineers adapt the material into a low-cost workhorse suited to certain transistors, sensors and a host of other components.

“When you have a very thin film, it’s very difficult to study,” said Fernández-Ballester, assistant professor of mechanical and materials engineering at Nebraska. “So this is a hard problem. But the basis of it is: Can we manipulate the properties? Can we get something better by manipulating the crystallization process? And if we want to manipulate it, we need to better understand what’s going on and have a means to control the way it proceeds.”

Unlike most polymers, which fail to conduct electricity, P3HT is among a special class of so-called conjugated polymers that can. Heating P3HT into a molten form, then letting it cool, promises to offer some control over its semicrystalline structure: the way its atoms or molecules form ordered patterns that, in turn, can dictate how electricity and light pass through it.

But the nature of that process — which factors influence the crystallization, and how — has mostly eluded researchers, who have struggled even with how to properly investigate it. Capturing a signal from the minuscule amount of crystallization taking place in a nanoscopic material is challenging enough in its own right. Finding a way to do it as the crystallization is actually occurring only compounds the difficulty.

“With this particular study, what I was wondering was: If we take one of these specialty polymers — and P3HT is the most utilized, is widely available — do we actually know what we’re doing when we’re processing this and solidifying it?” Fernández-Ballester said.

Knowing that conjugated polymers are sensitive to particular electromagnetic waves, Fernández-Ballester and her team turned to UV and visible light. When the P3HT was still molten, the polymer absorbed mostly UV light or the violets, blues and other wavelengths on the lower end of the visible spectrum. As the crystallization commenced, though, the material began absorbing oranges and reds. By tracking that absorption at every temperature, from the highs of molten polymer through the lows of cooled material, the team managed to track real-time crystallization throughout the P3HT.

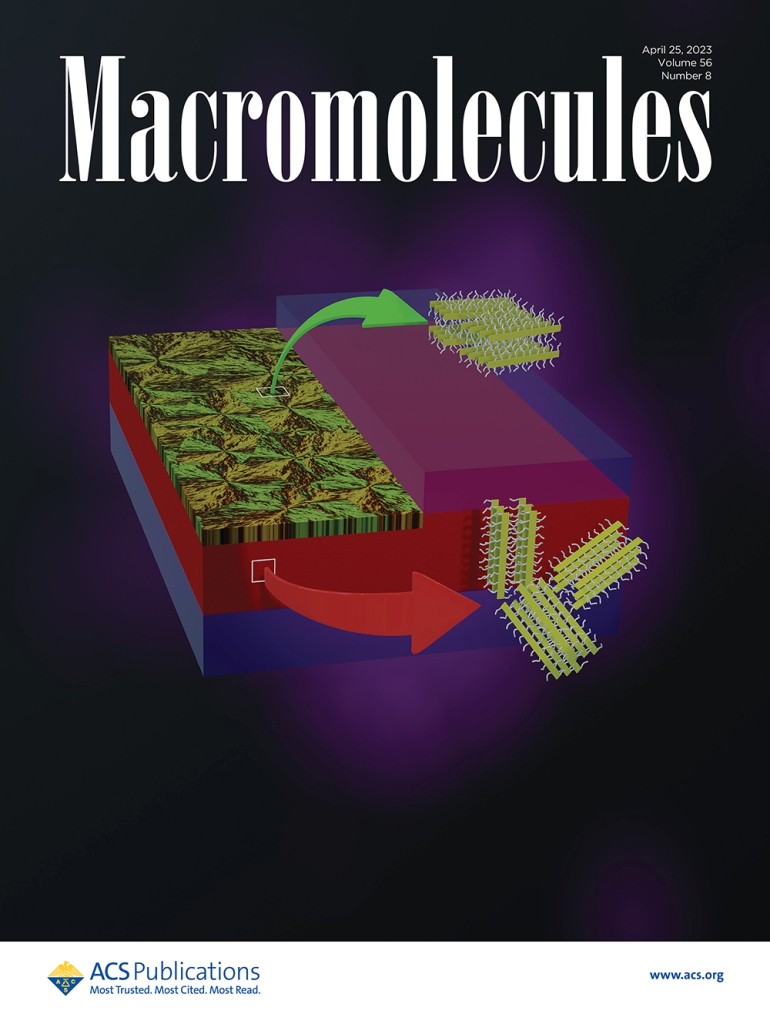

Fernández-Ballester was especially interested in how crystallization might vary depending on whether the top surface of the P3HT was either covered or freely exposed to air. So the team ran two experiments: one with glass atop it, and one without. When the top surface was free — and only then — the crystallization took on a two-step, two-tier process. The top 20 nanometers of the P3HT, a cross-section 5,000 times or so thinner than a hair, crystallized at about 445 degrees Fahrenheit — roughly 45 degrees higher than the rest of the polymer.

Thanks to some X-ray scattering experiments run at the Argonne National Laboratory, the team determined that, within the 20-nanometer crust, the ringed backbones of the polymer stacked together while also standing on their edges. That combination of order and orientation typically favors conductivity that runs parallel to the material’s surface, marking the crust as prime real estate for fabricating certain transistors — the tiny elements that regulate the flow of electricity through circuits.

Below that crust, the crystalline orientation depended in part on the thickness of the film itself. When the total film was no more than 40 nanometers thick, crystallites in the lower layer adopted essentially the same order and orientation as those above. In thicker films, that crystallinity eventually gave way to more disorder, so that the farther a crystallite resided from the crust, the more likely it was to adopt a random orientation. Instead of encouraging electricity to flow horizontally, a haphazard orientation should enable electric charges to flow in any direction — including from top to bottom, which could prove useful in solar cells.

“Different electronic devices do actually need the transport of charges to be in certain directions, which depends on what the electronic device is,” Fernández-Ballester said. “So anything that tells us either how to manipulate that, or how to get rid of that orientation, then has potential to guide the design of polymers for a particular application.

“Essentially, you’re then at that point of using rational design of the material and the processing to get the structure that you need. So you have an informed way of doing it; it’s not just trial and error.”

While calling the work “extremely fundamental,” Fernández-Ballester said the daunting complexity of conjugated polymers — of isolating variables that are so entangled, and on such a minuscule scale — makes it an essential step on the way to maximizing P3HT.

“I think there’s a synergy,” she said, “between the fundamental and the downstream, more applied research.”

The team reported its findings in the journal Macromolecules, which featured the study on the cover of its most recent issue. Fernández-Ballester authored the study with doctoral student Jesse Kuebler and Husker alumnus Tucker Loosbrock, along with Joseph Strzalka of the Argonne National Lab. The researchers received support from the National Science Foundation.