As every Nebraskan knows, wind can pack a powerful punch. Wind turbines, which capture all that energy, routinely suffer the wind’s abuses.

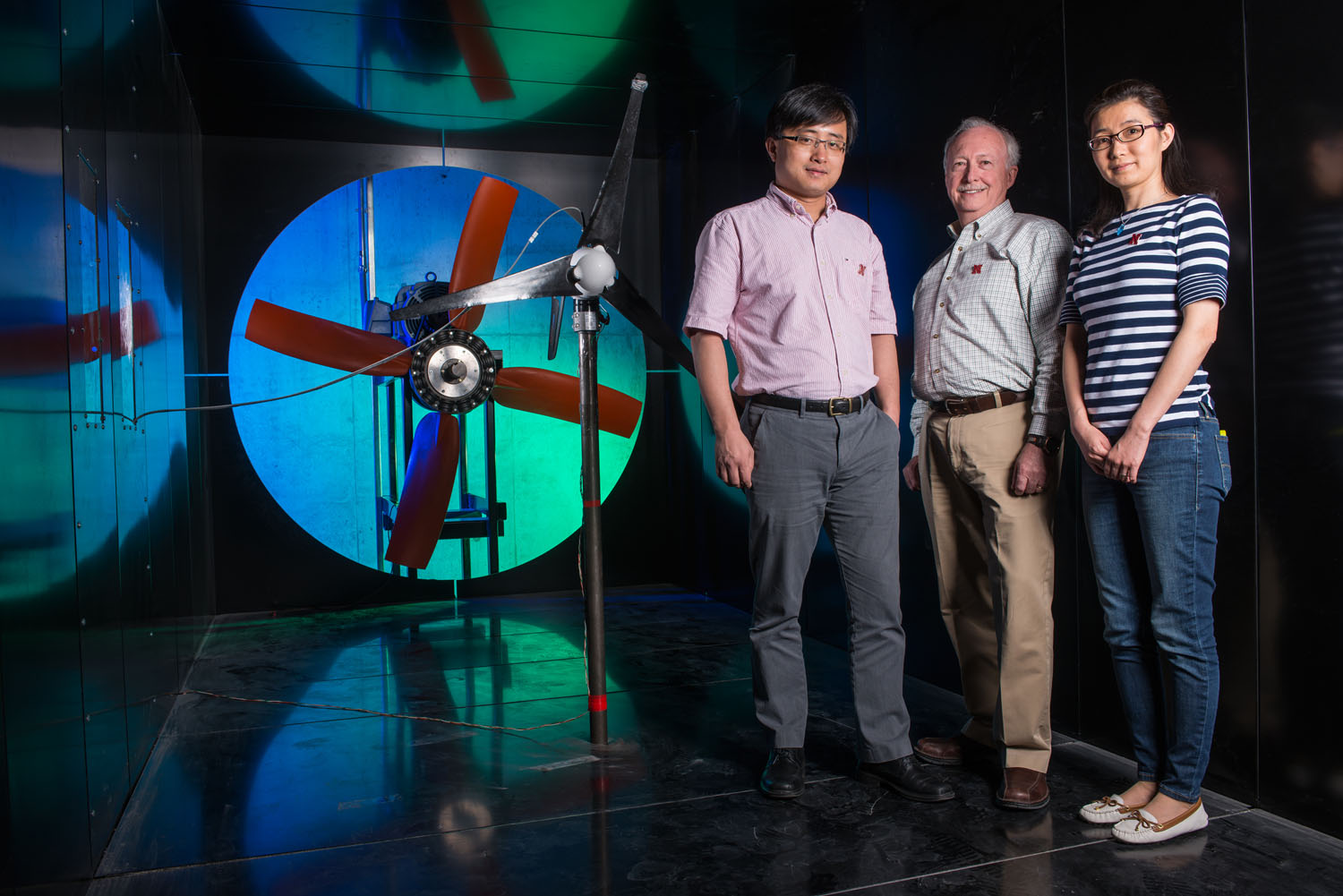

Maintaining turbines significantly increases the cost of wind power. A UNL team, in collaboration with GE Global Research, is developing technology to reduce that cost. Supported by a $1.5 million U.S. Department of Energy grant, the project will help the nation capitalize on an important renewable energy source. “Wind turbines operate under harsh conditions and require frequent inspections,” said project leader Wei Qiao, associate professor of electrical and computer engineering. “The cost of wind energy is very high, so we want to develop a system to reduce maintenance costs and extend the life span of wind turbines.”

Currently, maintenance requires a technician to head to remote, sometimes offshore, locations to scale turbines and inspect them manually. Finding a turbine in working order wastes time, but a damaged turbine not caught early enough often leads to more extensive and costly repairs.

UNL engineers are developing a system to remotely monitor, in real time, turbine function and to predict deterioration before it fails. The information will help operators and maintenance personnel better schedule inspections and repairs.

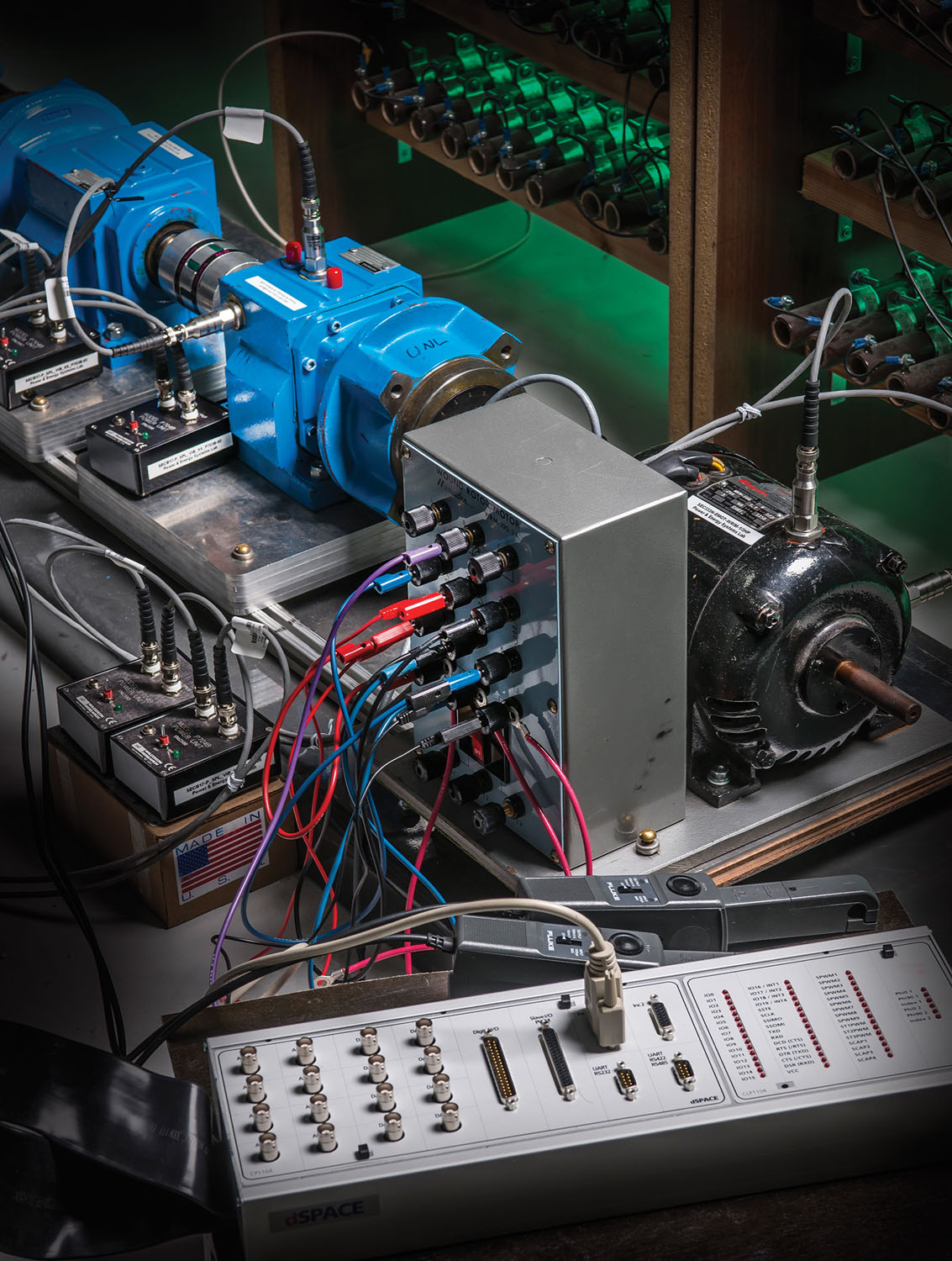

Traditional turbine monitoring systems use vibration sensors and other expensive equipment that also require maintenance and can fail.

To keep costs low, UNL engineers are piggybacking on control sensors already built into turbines. The challenge is finding and extracting only the information indicative of turbine health from within that larger data stream.

Qiao’s team is using signal-processing technology to develop ways to detect faults and predict their development over time using relevant electrical signals.

They plan to make a prototype system and test it on wind turbines installed at Nebraska high schools and community colleges. Collaborators at GE, the largest U.S. wind turbine manufacturer, will evaluate the system on larger wind turbines at sites nationwide.

This is part of Qiao’s broader research to improve wind turbines and smart power grid technologies. The National Science Foundation also funds this research.