Makers Supply Face Shields

As the coronavirus advanced, Nebraska faced a shortfall of face shields to protect its health care workers. To fill the need, a Husker team partnered with businesses and volunteers to manufacture 21,000 face shields for the Bryan Health system and the University of Nebraska Medical Center.

What began as a group of volunteers and staff 3D printing and assembling parts at Nebraska Innovation Studio on Nebraska Innovation Campus quickly morphed into a monumental effort to scale up production. Partnerships with the University of Nebraska-based National Strategic Research Institute and private companies were critical to success.

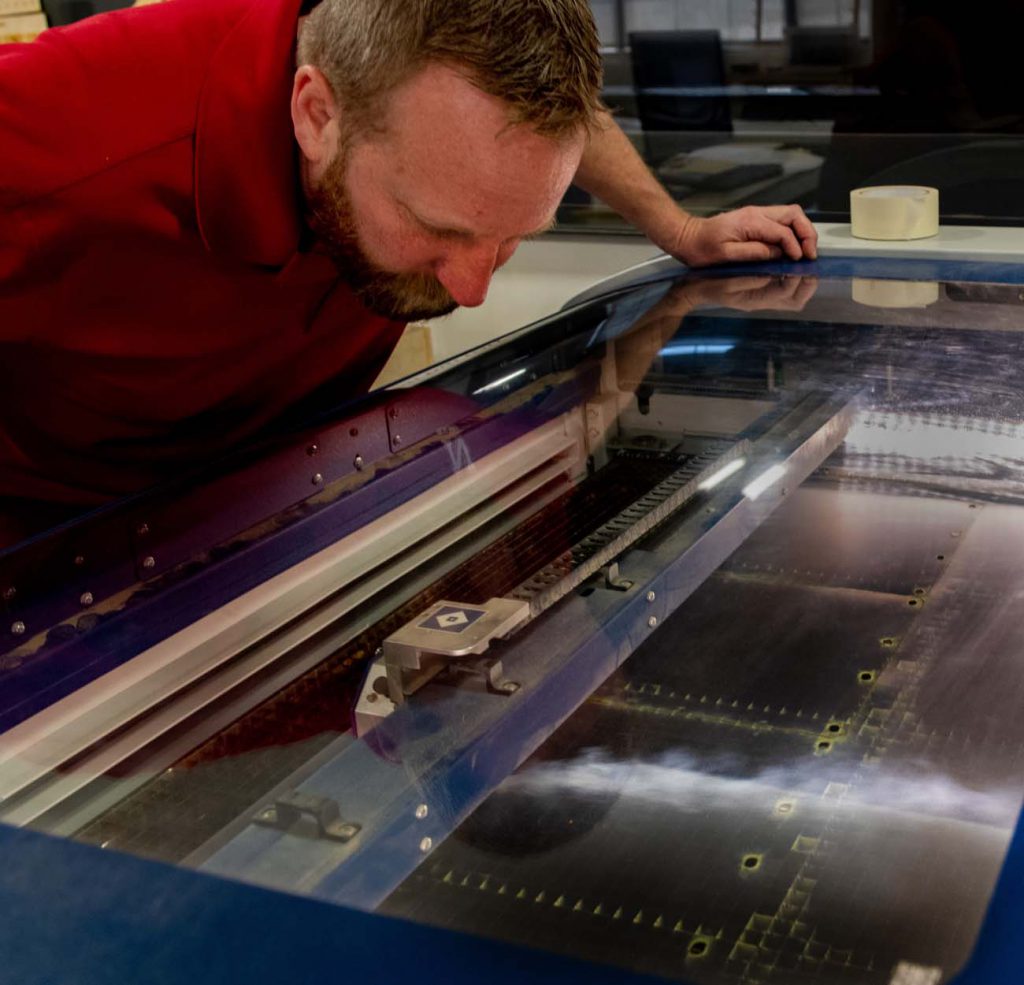

Jerry Reif, NIS shop manager, laser cuts plastic sheeting for face shields.

Instructional technician Max Wheeler assembles face shields with parts manufactured at Innovation Studio.

Within days, Nebraska engineers began the injection molding parts process, which is faster than 3D printing, with materials supplied by local companies. Volunteers and staff continued making and assembling parts at Innovation Studio, said Shane Farritor, Lederer Professor of Engineering and the studio’s executive chairman of the board of advisers.

“That’s pretty special. This may be the reason Innovation Studio exists – where people come together to make stuff happen that helps others,” Farritor said.

+ Additional content for Makers Supply Face Shields

Media mention: Innovation Studio, Kawasaki tool up to fill order for thousands of face shields (Lincoln Journal Star, 5/19/2020)