NEAT Labs Show Potential to Transform Manufacturing

A new, cutting-edge 3D printing laboratory is positioning Nebraska as a hub for additive manufacturing.

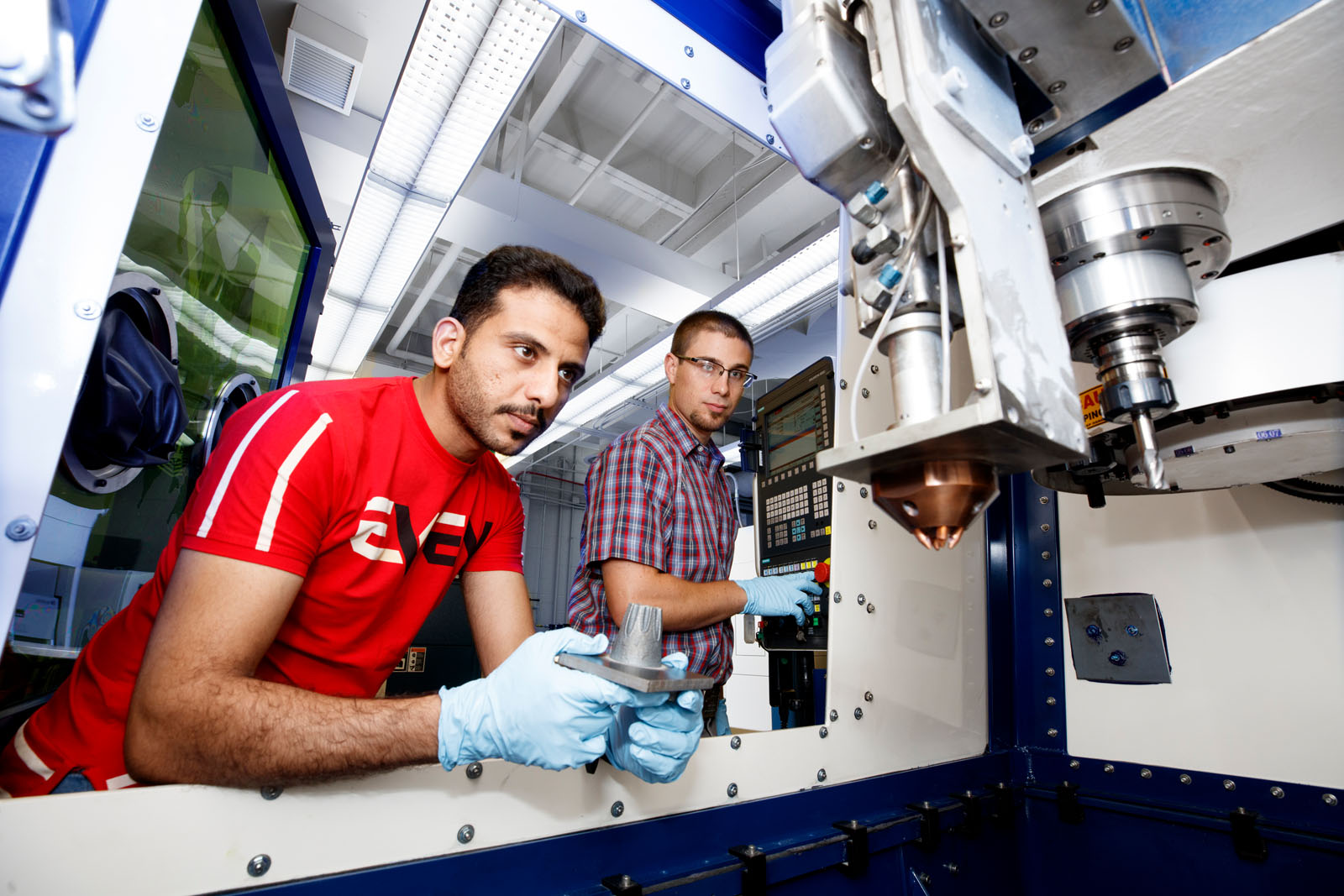

Opened in spring 2018, the Nebraska Engineering Additive Technology Labs feature three unique hybrid 3D printers. They can add or subtract a variety of materials – from plastics to titanium – to create complex three-dimensional shapes using less material than conventional technology.

The labs enable researchers and students to create projects using highly reactive materials. This process accommodates creation of intricate geometries, such as lattice structures and complex internal cooling channels for aerospace applications.

“If this research is successful, it will have a huge impact on how quickly and reliably we can turn around new products and design, spurring innovation in Nebraska.”

Prahalada Rao

The labs aim to provide a state-of-the-science regional hub for additive manufacturing technology, creating opportunities for collaborations among university researchers and industry. It is part of the Nano-Engineering Research Core Facility.

“If this research is successful, it will have a huge impact on how quickly and reliably we can turn around new products and design, spurring innovation in Nebraska,” said Prahalada Rao, assistant professor of mechanical and materials engineering.

+ Additional content for NEAT Labs Show Potential to Transform Manufacturing

Nebraska Engineering expands 3D printing capabilities