- Menu

-

Enhancing Sorghum for Biofuel Production

Food, Energy and Water

-

Getting to the Root of Crop Improvements

Plant Science

-

New Chancellor Envisions Bold Future for Research

Leadership

-

NU FEWS Sparks Innovation in Food, Energy and Water

Food, Energy and Water

-

Closing Achievement Gap for Kids

Early Childhood

-

Enhancing Early Childhood Development

Early Childhood

-

Drones Could Help Fight Fire with Fire

Unmanned Aerial Vehicles

-

Surprising Discovery Contradicts Predictions

X-ray Material

-

Laser Creates Surfaces that Mimic Nature

Laser Research

-

USSTRATCOM Delegation Visits UNL

Defense Research

-

Prospecting with Biosensors at Home or in the Field

Chemistry

-

Gift Creates Johnny Carson Emerging Media Arts Center

Media Arts

-

System Helps Diagnose, Treat Brain Damage

Health

-

UNL Hosts University, Industry Leaders

Industry Relations

-

Momentum Builds on Nebraska Innovation Campus

Economic Development

-

Bioinformatics Focus for NIC’s First Faculty Startup

Bioinformatics

-

Improving Surgery through Robotics

Robotics

-

CD Celebrates Collaboration with Philip Glass

Performing Arts

-

Strengthening Region’s Nanotech Assets

Nanoscience

-

Geospatial Technology Helps Restore Wetlands

Environment

-

Maximizing Innate Talent

Leadership

-

Early Career Awards Boost Promising Research

Honors

-

Research Highlights

-

Accolades

-

Financials

-

Credits

-

On the Cover

- PDF version

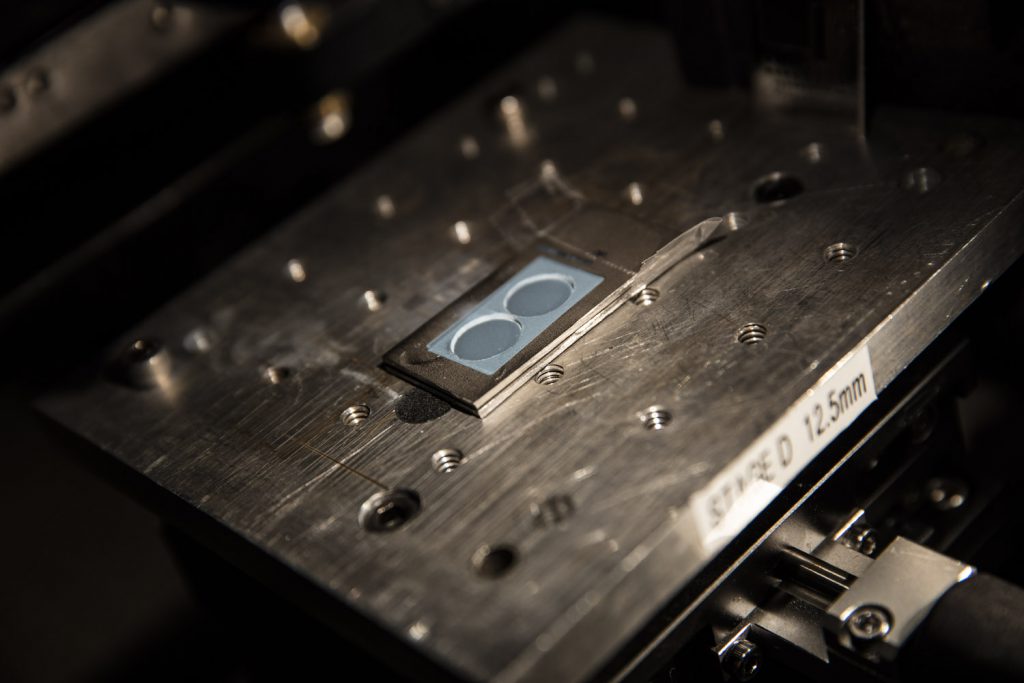

Laser Creates Surfaces that Mimic Nature

Shark skin, rose petals and moth eyes.

This isn’t a weird memory test. It’s the seemingly random starting point of Dennis Alexander’s research. Each of these biological systems has a unique capability that the UNL engineer’s team is exploiting for defense and industrial purposes.

Alexander and colleagues use lasers to copy microscopic structures found in nature onto metal surfaces, giving them similar unique properties already honed by Mother Nature.

“Our structures are very important to the military, Boeing and NASA,” said Alexander, Kingery Professor of Electrical and Computer Engineering. “We’re emphasizing using these structures in harsh environments, but there really isn’t any metal surface we can’t functionalize.”

His team uses femtosecond laser surface processing, or short-burst laser pulses, to alter the top 100 microns of a metal surface, about the depth of a human hair, producing surfaces that mimic nature. Altering the laser angle and other parameters creates surfaces with different properties.

Sharks, for example, are highly efficient swimmers. By copying their microscale skin onto metal, researchers create a super-hydrophilic, or wicking, material. This property reduces drag, so a shark skin-like submarine shell, for example, would be able to travel farther using less power.

UNL’s laser-created surfaces also improve heat transfer, important to many military and commercial systems.

Rose petals, in contrast, are super-hydrophobic. Rainwater slides off in beads. Super-hydrophobic surfaces also reduce drag. Applications include medical supplies that can’t be contaminated by blood or other fluids, antibacterial metals for joint replacements, reducing ice buildup on traffic lights and improving condenser heat exchangers, including those used to reclaim water in space.

Current hydrophobic materials are created with a polymer coating that adds weight and eventually breaks down, creating undrinkable water. For the International Space Station, where recycling water is paramount, a super-hydrophilic condenser would avoid these problems. Alexander’s team works with NASA on improved heat exchangers.

Remember moth eyes? To see at night and avoid detection by predators, moths absorb a wide spectrum of light. Mimicking the eye’s surface creates an anti-reflective metal, improving solar panel efficiency and making stealth aircraft harder to track.

NU’s National Strategic Research Institute and NASA fund this research.